Some machines use enormous tool libraries and retail store dozens of tools to be used in numerous area of interest apps.

Benefits of CNC machining: CNC machining gives several benefits, for instance high precision, accuracy, speed, efficiency, and flexibility. CNC machining can deliver complex and tailored parts which might be difficult or unattainable to generate by hand or with regular tools.

These early variations laid the groundwork for your CNC lathes that became integral in contemporary manufacturing.

Calibration. Both of those the tool and component ought to be setup in the best way. If nearly anything is off, The end result will likely not satisfy the demands.

EDM machines use current discharges and An electrical discipline to remove chips in the workpiece. Two electrodes are applied, with electrical fields intensified by moving the electrodes nearer to each other in order to Minimize parts. A dielectric liquid separates the two electrodes and facilitates the voltage.

So, that’s the main target of this text. We are going to ultimately deal with some advanced machines Sooner or later, but for now, Permit’s center on the very best CNC lathes in right now’s sector.

Stainless-steel: Renowned for its toughness and corrosion resistance, stainless-steel is a well-liked choice for programs that involve longevity and longevity.

By following these stage-by-phase processes in CNC turning, brands can achieve precise and efficient machining of cylindrical components with dependable quality and accuracy.

Initiating the machining cycle and starting off the rotation of the workpiece within the predetermined speed.

ABS Plastic: ABS is usually a hardy, impact-resistant plastic that machines effectively, making it an outstanding option for long lasting parts and prototypes.

It could possibly produce complex parts with restricted tolerances, rendering it an excellent choice for intricate patterns. CNC lathes are specially economical and specific in achieving these tight tolerances.

In distinction, CNC milling consists of a workpiece secured to your movable table. In such cases, the cutting tool rotates and moves to the metal piece, eliminating material and making a flat surface.

They need the accuracy and repeatability of a CNC lathe, and they would like to reduce the mess of coolant splashing from a guide lathe.

Just one-place turning tool can accomplish the Minimize in a single move Should the width with the Minimize Shop now is identical to the tool’s width. Normally, multiple cuts are needed.

Richard "Little Hercules" Sandrak Then & Now!

Richard "Little Hercules" Sandrak Then & Now! Talia Balsam Then & Now!

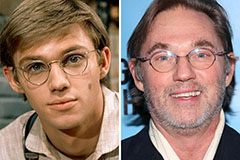

Talia Balsam Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Samantha Fox Then & Now!

Samantha Fox Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now!